HDPE Geomembranes: A Reliable Solution for Containment

2025-02-18 15:00

Summarize

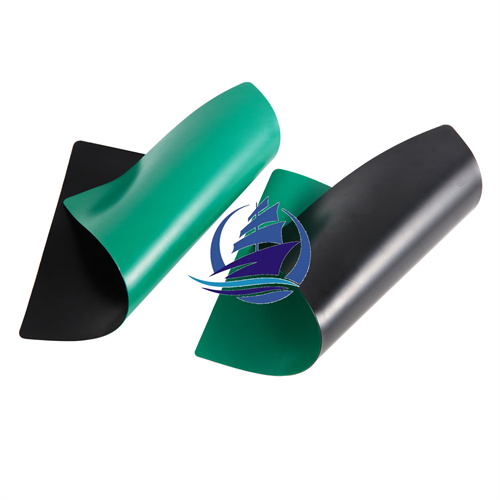

When it comes to robust and dependable containment solutions, HDPE geomembranes and HDPE textured geomembranes shine as top choices for engineers and project managers alike. These high-density polyethylene (HDPE) liners offer exceptional durability, chemical resistance, and versatility, making them ideal for applications like landfills, ponds, and mining operations. With a proven track record in geotechnical engineering, HDPE geomembranes provide an impermeable barrier that safeguards the environment while ensuring project longevity. In this blog, we’ll explore the technical brilliance of these materials, their standout features, and why they’re a go-to option for modern containment needs—all delivered with a steady hand and a sprinkle of enthusiasm!

The Technical Edge of HDPE Geomembranes

HDPE geomembranes are crafted from high-density polyethylene, a polymer known for its tightly packed molecular structure. This density—typically above 0.94 g/cm³—gives these liners their remarkable strength and resistance to harsh chemicals, UV rays, and environmental wear. Whether it’s a smooth sheet or an HDPE textured geomembrane with a roughened surface, these liners are engineered to perform under pressure. The manufacturing process, often involving extrusion or blown film techniques, ensures uniform thickness and quality, with options ranging from 0.5 mm to 3.0 mm to suit various project demands.

What sets HDPE geomembranes apart is their ability to balance toughness with flexibility. They can stretch and adapt to uneven surfaces without cracking, a trait that’s critical for installations on challenging terrains. Add to that their low permeability—measured in nanometers per second—and you’ve got a barrier that locks in liquids and gases with precision. For projects requiring steep slopes or extra stability, HDPE textured geomembranes step up with their enhanced friction, preventing slippage and ensuring a secure fit against soil or geotextiles.

Why Choose HDPE Geomembranes?

The appeal of HDPE geomembranes lies in their practical benefits. First, their chemical resistance is a game-changer. From acidic leachates in landfills to corrosive mining byproducts, these liners hold strong where others might falter. Second, their UV resistance—boosted by additives like carbon black—means they can endure years of sun exposure without breaking down. Buried underground? Expect a lifespan stretching 50 to 100 years, depending on conditions. Exposed to the elements? You’re still looking at 20 to 30 years of reliable service.

Then there’s the cost factor. HDPE geomembranes deliver high performance without breaking the bank, offering a budget-friendly alternative to traditional materials like concrete or clay. Installation is straightforward too, thanks to their weldability. Using hot wedge or extrusion welders, technicians can create seamless joints that are as strong as the liner itself. For HDPE textured geomembranes, the added surface grip reduces the need for extra anchoring, saving time and effort on sloped sites.

Applications That Showcase Versatility

The uses for HDPE geomembranes are as diverse as the industries they serve. In landfills, they act as a shield, keeping leachate from seeping into groundwater. For water management, they line reservoirs and canals, minimizing seepage and maximizing efficiency. In mining, HDPE textured geomembranes are a staple for heap leach pads and tailings ponds, containing hazardous materials with confidence. Even aquaculture benefits, with these liners ensuring ponds retain water and maintain quality for fish farming. Wherever containment is critical, HDPE geomembranes deliver peace of mind.

FAQs :

What’s the difference between smooth and textured HDPE geomembranes?

Smooth HDPE geomembranes have a flat surface, ideal for flat or gently sloped areas needing a uniform barrier. HDPE textured geomembranes, with their rough finish, boost friction for stability on steep slopes or layered systems, making them perfect for demanding terrains.

How long do HDPE geomembranes last?

It depends on exposure. Buried HDPE geomembranes can last 50–100 years due to protection from UV and weather. Exposed liners typically endure 20–30 years, thanks to UV-resistant additives that fend off degradation.

Are HDPE geomembranes environmentally friendly?

Yes! They’re inert, non-toxic, and recyclable at the end of their life. By preventing leaks and contamination, they protect ecosystems, aligning with sustainable engineering goals.

Conclusion

HDPE geomembranes and HDPE textured geomembranes are more than just liners—they’re a testament to smart engineering and environmental stewardship. With their blend of strength, flexibility, and affordability, they tackle the toughest containment challenges with ease. Whether you’re sealing a landfill, securing a slope, or storing water, these liners offer a solution you can trust. Backed by decades of proven performance and a cheerful nod to innovation, HDPE geomembranes are here to keep your projects solid and successful for years to come.