Is Geomembrane Permeable?

2024-12-19 18:28

Defining Impermeability in the Context of Geomembranes

The Science Behind Geomembrane Impermeability

Polymer Selection: Geomembranes are typically made from polymers like High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), Polyvinyl Chloride (PVC), and Ethylene Propylene Diene Monomer (EPDM). These polymers are inherently resistant to the passage of liquids and gases due to their molecular structure and chemical properties. Manufacturing Process: The manufacturing process plays a crucial role in ensuring the geomembrane's impermeability. Modern manufacturing techniques produce continuous sheets with minimal defects, reducing the potential for leaks. Quality control measures during production are essential to maintain the integrity and impermeability of the final product. Thickness and Density: The thickness and density of a geomembrane sheet also contribute to its impermeability. Thicker and denser geomembranes generally offer greater resistance to permeation. Choosing the right thickness depends on the specific application and the substances being contained. Working with a knowledgeable geomembrane company can help you select the appropriate thickness for your project. Seaming and Welding: While the geomembrane sheet itself is impermeable, the seams where panels are joined can be potential weak points. Proper seaming and welding techniques are crucial to ensure a continuous, impermeable barrier. Experienced installers from a reputable geomembrane company utilize specialized equipment and techniques to create strong, leak-proof seams.

Testing and Verification of Impermeability

Leakage Rate Testing: This test measures the rate at which liquids or gases pass through the geomembrane under specific conditions. Water Vapor Transmission Testing: This test measures the rate at which water vapor permeates through the geomembrane. Chemical Compatibility Testing: This test evaluates the geomembrane's resistance to degradation or permeation by specific chemicals it will be exposed to in its intended application.

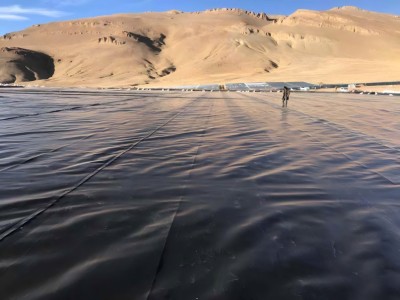

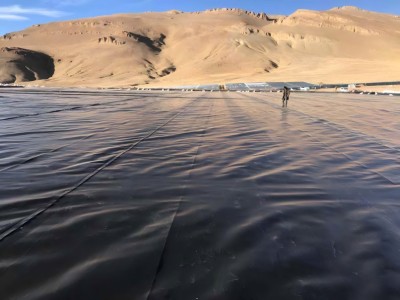

Applications of Impermeable Geomembranes

Landfill Liners: Geomembranes prevent leachate from contaminating soil and groundwater. Mining: They contain tailings and prevent the release of hazardous materials. Water Management: Geomembranes line reservoirs, canals, and ponds, preventing water loss due to seepage. Wastewater Treatment: They line wastewater treatment facilities, preventing contamination of the surrounding environment. Oil and Gas: Geomembranes prevent spills and leaks in oil and gas exploration and production. Aquaculture: They create contained environments for fish farming and other aquaculture operations. Agriculture: Geomembranes are used for irrigation canals, farm ponds, and other water containment systems. Shape geomembranes can be custom-fabricated for specific agricultural layouts.

Choosing the Right Geomembrane for Your Project

Chemical Compatibility: The geomembrane material must be compatible with the substances it will be containing. Site Conditions: Factors like soil type, temperature fluctuations, and UV exposure influence the choice of geomembrane. Longevity Requirements: The expected lifespan of the geomembrane should align with the project’s duration. Budget: While cost is a consideration, prioritize quality and suitability for the application. Shape and Size: Shape geomembranes offer customized solutions for complex projects or unique design requirements.