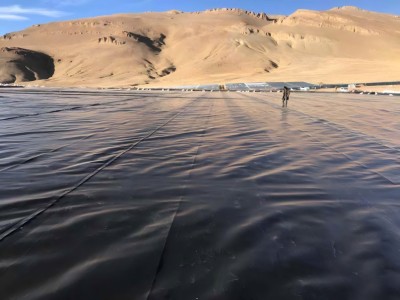

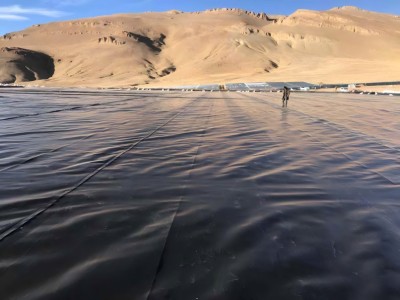

High-Density Polyethylene (HDPE) Geomembranes

HDPE geomembranes are among the most commonly used types. They are known for their excellent chemical resistance, making them suitable for containing a wide range of substances, including hazardous waste. HDPE geomembrane liners are often found in landfills, mining operations, and industrial wastewater treatment facilities. When sourcing HDPE geomembranes, it's essential to work with a reputable geomembrane company that can guarantee the quality and performance of their products. The right geomembrane sheet will provide long-term protection and prevent costly leaks.

Linear Low-Density Polyethylene (LLDPE) Geomembranes

LLDPE geomembranes share some similarities with HDPE but offer increased flexibility and elongation properties. This makes them ideal for applications where the liner needs to conform to irregular surfaces or withstand significant stress. LLDPE geomembrane sheets are often used in aquaculture, canals, and reservoirs. Working with a reliable geomembrane factory ensures that the LLDPE geomembrane you select meets the required quality and performance standards.

Polyvinyl Chloride (PVC) Geomembranes

PVC geomembranes are known for their high strength and resistance to UV radiation and weathering. They are commonly used in exposed applications, such as pond liners, covers for agricultural silage, and rooftop gardens. However, PVC geomembranes can be susceptible to certain chemicals, so it's crucial to consult with a geomembrane company to ensure compatibility with the intended application. The selection of the appropriate PVC geomembrane liner depends on factors like thickness and specific formulation.

Ethylene Propylene Diene Monomer (EPDM) Geomembranes

EPDM geomembranes are highly flexible and resistant to weathering, ozone, and a wide range of chemicals. They are often used in potable water applications, such as reservoir liners and water storage tanks. EPDM also has excellent low-temperature flexibility, making it suitable for cold climates. When choosing an EPDM geomembrane sheet, partnering with a reputable geomembrane manufacturer guarantees quality and long-term performance.

Shape Geomembranes: Customized Solutions

Beyond the standard roll form, geomembranes can be fabricated into specific shapes and sizes, creating shape geomembranes. This customization allows for precise fitting in complex applications, such as lining irregular ponds, creating custom-shaped tanks, or covering unique structures. Working with a skilled geomembrane factory is crucial when designing and manufacturing shape geomembranes, as precision and quality are essential for preventing leaks and ensuring long-term integrity.

Other Geomembrane Materials

While the above examples represent the most commonly used geomembrane materials, other specialized options exist, including:

Polypropylene (PP) geomembranes: Offer high chemical resistance and temperature stability.

Chlorinated polyethylene (CPE) geomembranes: Provide excellent flexibility and chemical resistance.

Polyurethane (PU) geomembranes: Known for their high strength and abrasion resistance.

A knowledgeable geomembrane company can provide guidance on selecting the most appropriate material for your specific project needs.

Importance of Quality and Choosing the Right Supplier

The success of any project involving geomembranes hinges on the quality of the material and the expertise of the supplier. Here's why choosing a reputable geomembrane company and a trusted geomembrane factory is so important:

Material Expertise: A reputable supplier understands the nuances of different geomembrane materials and can recommend the best option for your specific application. They can also advise on appropriate thickness, seam welding techniques, and other critical factors.

Quality Control: A reliable geomembrane factory adheres to strict quality control standards, ensuring that the geomembrane sheet or geomembrane liner meets industry specifications and performance requirements. This minimizes the risk of defects and ensures long-term reliability.

Technical Support: A good geomembrane company provides technical support throughout the project lifecycle, from initial design and material selection to installation guidance and troubleshooting.

Shape Geomembrane Expertise: If your project requires shape geomembranes, a skilled manufacturer with experience in custom fabrication is essential.

Conclusion

Geomembranes play a vital role in numerous applications, protecting the environment, conserving resources, and ensuring the integrity of critical infrastructure. Understanding the different types of geomembranes, including HDPE, LLDPE, PVC, EPDM, and specialized shape geomembranes, is crucial for selecting the right solution for your project. Partnering with a reputable geomembrane company and a trusted geomembrane factory ensures access to high-quality materials, expert advice, and technical support. By making informed decisions and prioritizing quality, you can ensure the long-term success and sustainability of your projects. Don't hesitate to reach out to a geomembrane expert to discuss your specific needs and find the perfect geomembrane solution.