What is the lifespan of woven geotextile fabric?

2024-06-30 15:00

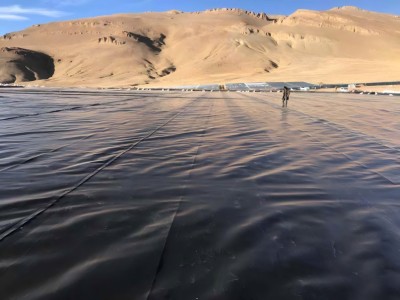

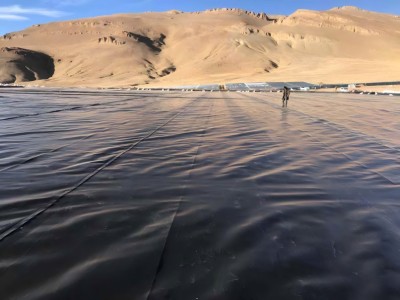

Woven geotextile fabrics, sometimes referred to as woven geotextile membranes, are workhorses in the construction industry. They provide vital separation, filtration, and reinforcement functionalities in various projects, from roads and driveways to erosion control and landfill construction. But like any building material, understanding its lifespan is crucial for informed decision-making. This blog post dives into the factors influencing the lifespan of woven geotextile fabric, equipping you with realistic expectations for your projects.

Key Factors Affecting Lifespan

Several factors significantly influence the longevity of woven geotextile fabric:

· Material Composition: The type of polymer used in the fabric plays a crucial role. Polypropylene (PP) is the most common material, offering excellent chemical resistance and durability. However, high-density polyethylene (HDPE) might be preferred for projects requiring superior puncture resistance.

· Fabric Weight and Strength: The weight (often measured in oz/yd²) and tensile strength of the fabric directly impact its durability. Thicker and stronger fabrics offer a longer lifespan, particularly in demanding applications.

· Exposure Conditions: Ultraviolet (UV) light exposure can degrade the fabric over time. Choosing a UV-stabilized woven geotextile fabric is essential for projects exposed to direct sunlight for extended periods.

· Installation Methods: Improper installation practices can significantly shorten the lifespan of woven geotextiles. Following manufacturer's recommendations and ensuring proper seaming techniques are crucial for optimal performance.

· Chemical and Biological Environment: Exposure to harsh chemicals or biological activity can affect the fabric's integrity. Specifying a fabric resistant to the specific chemicals encountered in your project is vital.

Expected Lifespan Range

Under ideal conditions, with proper material selection, installation, and minimal environmental stressors, woven geotextile fabrics can offer a lifespan exceeding 50 years. However, this is a best-case scenario.

A more realistic range for many projects falls between 15-30 years. Factors like UV exposure, chemical environments, and demanding mechanical stresses can shorten this timeframe.

Pro Tip: Always consult with a geotextile specialist when planning your project. They can assess your specific requirements and recommend a woven geotextile fabric with the appropriate lifespan for your needs. You can also connect with reputable woven geotextile fabric suppliers who can provide expert advice and ensure you source high-quality fabrics from reliable woven geotextile factories.

Maximizing the Lifespan of Woven Geotextiles

Here are some additional tips to maximize the longevity of your woven geotextile fabric:

· Storage: Store the fabric in a cool, dry, and protected location before installation to avoid premature degradation.

· Backfilling: Use clean, well-graded backfill materials to minimize punctures and abrasion during construction.

· Inspections: Conduct regular inspections of the fabric after installation to identify and address any potential damage promptly.

Conclusion

Understanding the factors influencing the lifespan of woven geotextile fabrics empowers you to make informed decisions for your project. By considering material selection, installation practices, and potential environmental stressors, you can maximize the performance and longevity of this crucial construction material.

Do you have any questions about the lifespan of woven geotextiles or finding the right product? Contact us today to help you get the right product for your needs.